Advancements in EV Battery Recycling: Technology and Future

- August 3, 2024

Explore the latest advancements in EV battery recycling technologies, addressing environmental impact, and future innovations for a sustainable EV industry.

9621 Agnes Crossing, Lake Suzanneview, New Mexico Island 84604-9295.

Explore the latest advancements in EV battery recycling technologies, addressing environmental impact, and future innovations for a sustainable EV industry.

The rise of electric vehicles (EVs) represents a pivotal shift in the automotive industry, driven by the need to reduce carbon emissions and dependence on fossil fuels.

As EV adoption accelerates globally, the focus has increasingly turned toward managing the lifecycle of EV batteries, particularly when they reach the end of their useful life.

The need for advanced recycling technologies has become paramount to minimize environmental impact, recover valuable materials, and ensure the sustainability of the EV revolution.

This article delves into the importance of EV battery recycling, explores recent technological advancements, examines the challenges and opportunities in the field, and looks toward future innovations.

With the global expansion of the electric vehicle market, the volume of used EV batteries is set to increase dramatically.

Effective recycling of these batteries is critical not only for environmental sustainability but also for economic efficiency and resource conservation.

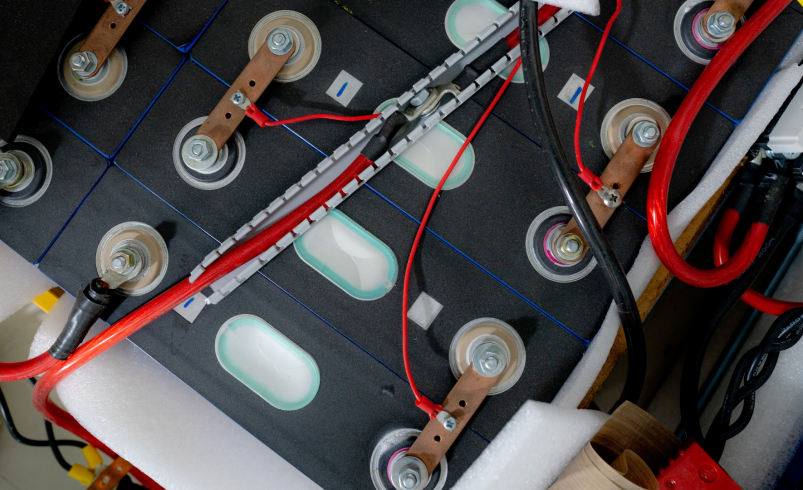

Electric vehicle batteries, particularly lithium-ion batteries, contain a mix of valuable and potentially hazardous materials, including lithium, cobalt, nickel, and other rare earth elements.

If these batteries are not properly recycled, they pose significant environmental risks.

For instance, improper disposal can lead to the leaching of toxic chemicals into the soil and water systems, potentially contaminating ecosystems and posing health risks to humans and wildlife.

EV battery recycling helps mitigate these risks by ensuring that hazardous materials are handled and processed safely.

Advanced recycling technologies can also reduce the overall carbon footprint of the battery lifecycle by lowering the need for raw material extraction, which is often energy-intensive and environmentally damaging.

Moreover, by recovering and reusing materials from spent batteries, recycling contributes to the sustainability of the entire EV supply chain.

Beyond environmental considerations, there are substantial economic incentives for EV battery recycling.

The global demand for materials like lithium, cobalt, and nickel is rising, driven by the proliferation of EVs and renewable energy technologies.

Recycling can alleviate the pressure on mining operations by recovering these valuable materials from used batteries, thus reducing the reliance on virgin resources.

Additionally, recycling can lead to significant cost savings for manufacturers.

By integrating recycled materials into new battery production, manufacturers can lower production costs and reduce supply chain vulnerabilities associated with fluctuating raw material prices.

The recycling industry itself also presents economic opportunities, including job creation in sectors related to battery collection, dismantling, and processing.

The growing demand for efficient and cost-effective recycling methods has spurred significant advancements in EV battery recycling technologies.

This section explores the latest innovations in hydrometallurgical, pyrometallurgical, and direct recycling processes, which are at the forefront of this evolving industry.

Hydrometallurgical recycling is a chemical process that uses aqueous solutions to dissolve and separate valuable metals from battery materials.

This method has gained traction due to its ability to selectively recover metals with high purity levels, making it a preferred option for lithium-ion battery recycling.

Pyrometallurgical recycling involves the use of high-temperature processes to extract metals from battery materials.

This method is well-established in the recycling industry, particularly for the recovery of metals like cobalt and nickel.

However, recent advancements have focused on improving the energy efficiency and environmental impact of these processes.

Direct recycling, also known as physical or mechanical recycling, involves the direct reuse of battery components without breaking them down into raw materials.

This approach is gaining attention due to its potential to preserve the performance characteristics of battery components, thus reducing waste and promoting sustainability.

Despite the significant advancements in recycling technologies, several challenges must be addressed to fully realize their potential.

This section explores the technical, economic, and regulatory challenges that the industry faces, as well as the opportunities for overcoming these obstacles.

The technical complexity of EV battery recycling presents several challenges.

These batteries are composed of various materials and chemicals, each requiring different recycling processes.

This diversity complicates the development of universal recycling methods that are both efficient and cost-effective.

Batteries can still hold a charge, posing a risk of short circuits, fires, or explosions during handling and processing.

Moreover, the presence of toxic and flammable materials requires stringent safety protocols to prevent environmental contamination and protect workers.

Advanced recycling technologies must incorporate robust safety measures to mitigate these risks.

The economic viability of recycling technologies is influenced by several factors, including the cost of recycling processes, the market value of recovered materials, and the availability of infrastructure.

Effective recycling practices depend on a supportive regulatory and policy framework.

Governments and regulatory bodies play a crucial role in setting standards for battery disposal, encouraging the development of recycling technologies, and ensuring that recycling practices are environmentally sound.

Examining real-world examples provides valuable insights into how advancements in recycling technologies are being applied in practice.

This section highlights key initiatives from leading automotive manufacturers and research institutions that are driving innovation in EV battery recycling.

Automotive manufacturers are at the forefront of efforts to develop and implement advanced recycling technologies.

These companies recognize the importance of recycling in reducing the environmental impact of their products and securing a sustainable supply of materials.

Research institutions play a critical role in advancing recycling technologies by conducting cutting-edge research and collaborating with industry partners.

Academic studies provide the foundational knowledge needed to develop new recycling methods and improve existing ones.

The future of EV battery recycling is shaped by emerging technologies and the integration of recycling into a circular economy framework.

This section explores potential advancements and innovations that could further improve recycling practices and support the sustainable growth of the electric vehicle industry.

Several cutting-edge technologies hold promise for revolutionizing the field of EV battery recycling, making processes more efficient, cost-effective, and environmentally friendly.

Integrating recycling technologies into a circular economy framework promotes the sustainable use of resources and reduces waste.

In a circular economy, materials are kept in use for as long as possible, and products are designed with end-of-life considerations in mind.

The advancements in EV battery recycling technologies are crucial for managing the environmental impact of the growing electric vehicle industry.

As the demand for EVs continues to rise, so does the need for efficient and effective recycling solutions.

Recent developments in hydrometallurgical, pyrometallurgical, and direct recycling processes have significantly improved the recovery of valuable materials and reduced the environmental footprint of battery recycling.

However, challenges remain, including technical complexities, economic considerations, and the need for a supportive regulatory framework.

Looking forward, emerging technologies such as nanotechnology and AI, as well as the integration of recycling into a circular economy, offer promising pathways for further advancements.

As the industry evolves, continued innovation in recycling technologies will be essential to ensuring the sustainability of the electric vehicle revolution.